Standards in high-tech perfection, Standard parts are used as standardised products in tool construction, mould making and mechanical engineering. FIBRO standard parts mean ultimate precision. We are a global market leader working closely with our customers offering high availability, rapid delivery times, a first-class service and an outstanding price/performance ratio. The Standard Parts business unit is located at the FIBRO factories in Hassmersheim and Weinsberg in Germany.

This is where an extensive range of standard parts are produced, stored and shipped worldwide - including just-in-time. The product range for tool construction, mould making and mechanical engineering includes die sets, guide elements, low-maintenance oil-less guide elements, precision parts such as punches and matrices, compression springs, high-safety gas springs, metal forming materials, metal-bonding adhesives and casting resins, peripheral equipment for presses and tools, tool slide units with spline, roller or hydraulic drives and standard parts for mould making.

An important factor in the consistently high quality of our standard parts production is ongoing quality testing - from the raw material up to the finished product. We can achieve increased service lives, in particular on wear parts, such as punches, which allow our customers to benefit in the form of noticeable cost savings. Precision is the be-all and end-all for us. This applies to all elements of a tool. After all, the function of a tool is determined by the quality of its individual parts. FIBRO standard parts are synonymous with ultimate precision and reliability in tool manufacture, mould making and mechanical engineering. And that's something experienced engineers really value.

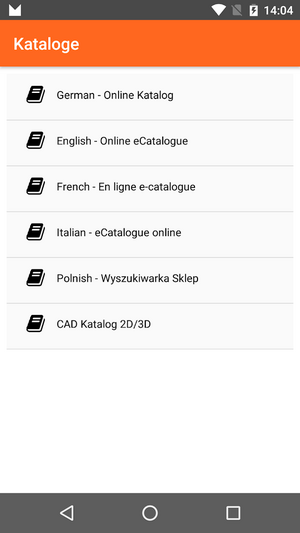

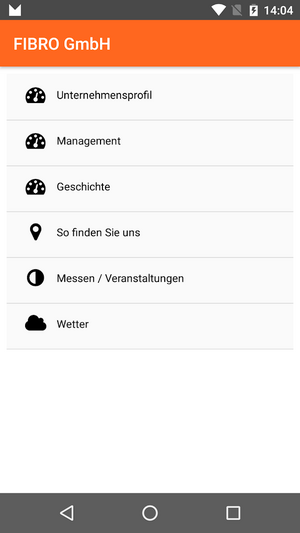

![[Translate to Italian:] Normalien APP](/fileadmin/_processed_/3/f/csm_FIBRO_APP_e331904e86.png)

![[Translate to Italian:] APP STORE](/fileadmin/FIBRO/Bilder/app_store.png)

![[Translate to Italian:] GOOGLE STORE](/fileadmin/FIBRO/Bilder/google_store.png)

![[Translate to Italian:] Download AKP file](/fileadmin/_processed_/8/b/csm_download_AKP_4d21039cb7.png)