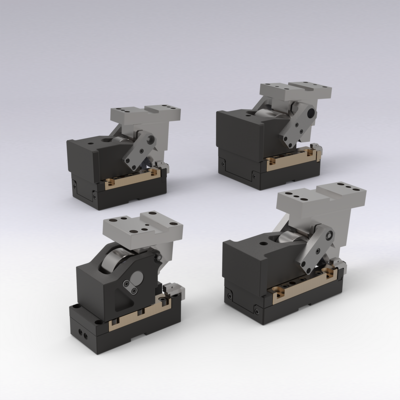

ROLLER SLIDE UNITS FRC

2017.43.

Our roller slide units series 2017.43 have been used in various dies for many years. They allow a working angle which can be individually adapted to the necessary requirements, and are ideal for use in punching operations.

The roller slide units are available in four widths and different stroke lengths. In comparison to cam units, the working angle in the permitted angular range can be selected virtually without restriction and without graduation.

The V-shaped guide, in combination with a solid roller, permits sufficiently high pressing forces and precise guidance. The guide, which is equipped with bronze or sintered sliding elements, reduces the required maintenance work and allows simple repair in the event of wear.

Our roller slide units are reset by gas springs. These gas springs used in these units, with the advanced safety features, are from our Standard Parts product range and offer the highest possible safety standard according to the Pressure Equipment Directive. The cam unit reset can be secured via forced retraction as an option, or as well as end position interrogation via a sensor. To improve operational safety, we recommend the use of forced retractions. The end position can also be queried by means of a sensor. Both versions can be selected as an option.

These cam units can be ordered ex works with a machined work surface according to your data set upon request.

Design features:

- Prism guide against cam base

- Solid roller against driver

- Steel sliding surfaces (induction hardened) / bronze with solid lubricant or sinter

- Different stroke lengths available

- Cam unit in the tool can be removed towards the rear

- Gas spring with safety features

- Forced retraction available as an option

- Idle position sensor monitoring available as an option

Our roller slide units are available in four widths from 78mm to 170mm, and can be used in a working angle range from -20 ° to 50°.