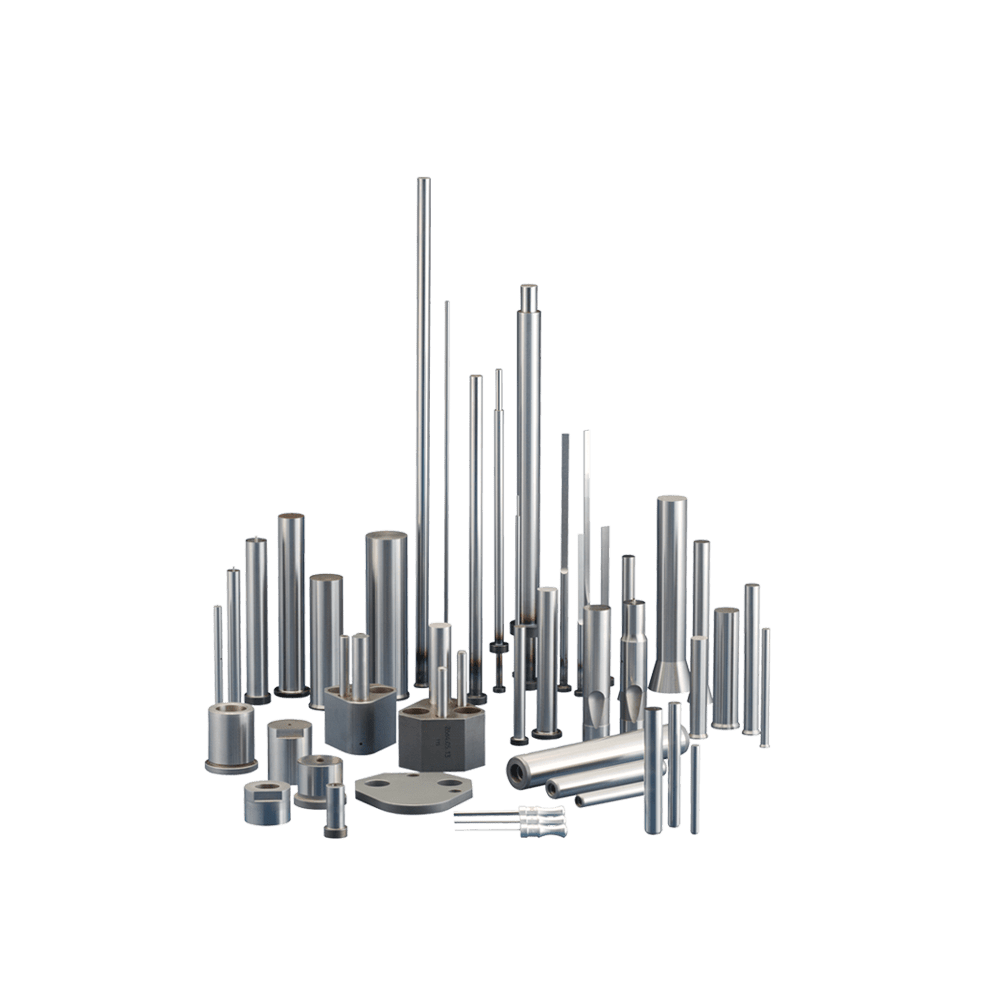

Our range of precision parts include punches with bevel/flat head or cylinder head according to DIN regulations or made to drawing in 8 different material qualities as well as quick-change punches.

All these high-wear parts benefit from the constant monitoring of quality that characterizes our entire standard parts fabrication process, from receipt of raw materials through to dispatch of the finished product. The result – an exceptionally long die life – cuts costs dramatically in the punching shop by reducing the need for tool changes.

ALSO AVAILABLE:

The construction and layout of components for production require a lot of time and expertise. Both are limited and costly resources.

To support you the best way possible with our expert knowledge in the user-specific selection of the suitable products, we have developed the FIBRO 3D Interactive Product Configurator.

The configurator includes our entire portfolio of punches and bushings and permits the individual selection of head shape and punch parameters. Through the selection of the sheet metal material and sheet thickness, the cutting clearance can be defined and then transferred to the configuration of the bush. Existing retainers can also be configured and attached. You receive your ready-to-order solution whose CAD data is also available directly as a download.

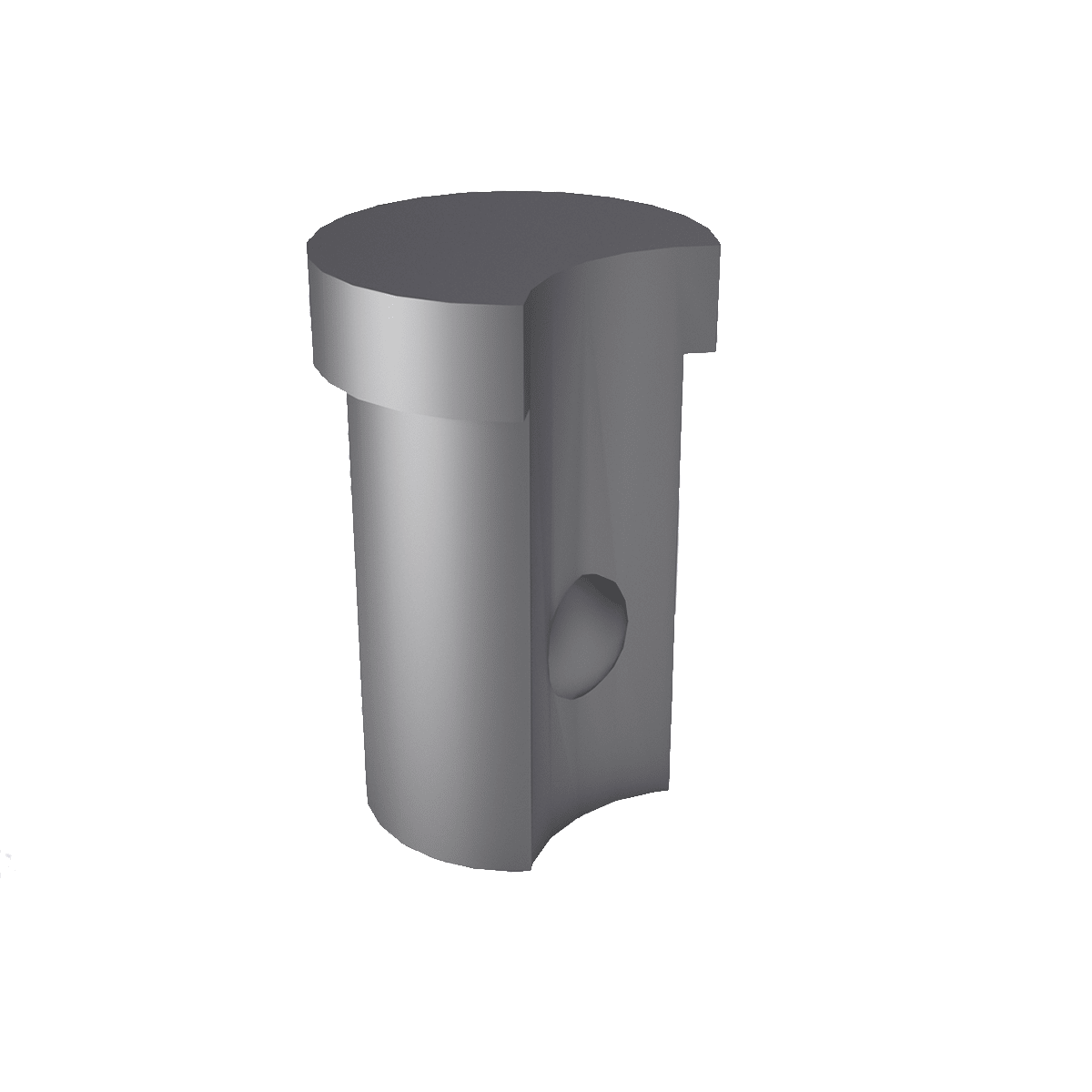

The Dynamic Stripper (DAE) is used in stamping tools for stamping processes with a material thickness of up to 2 mm. The DAE is located beneath the matrix.

The shape can be compared with a slotted sleeve (similar to collet chucks). After the actual stamping process, the cutting punch, together with the adherent slug, dips into the DAE. In doing so, the DAE expands and rests against the cutting punch. During the return stroke, the DAE removes the slug from the cutting punch, protecting the tool and the product from damages

The new holding inserts for quick-change punches are available in two versions, light and heavy-duty. They are installed directly in the tool plate; the previously neccessary additional mounting plate is no longer required. Only two holes for the punch and the holder/bracket have to be drilled.

Was it in the past not possible to place quick-change punches close to each other due to the external shape of the mounting late, the ACCU-LOCK holding inserts are practically no longer an obstacle.

Due to the design of the mounting plates, it is not possible to place the punches close together - now a few millimeters distance are no longer a problem. For example, the entire structure of tool slides can be made significantly more compact. FIBRO offers the holding inserts as individual parts and also in the future, with a multiple mounting plate made according to customer requirements, fully assembled.