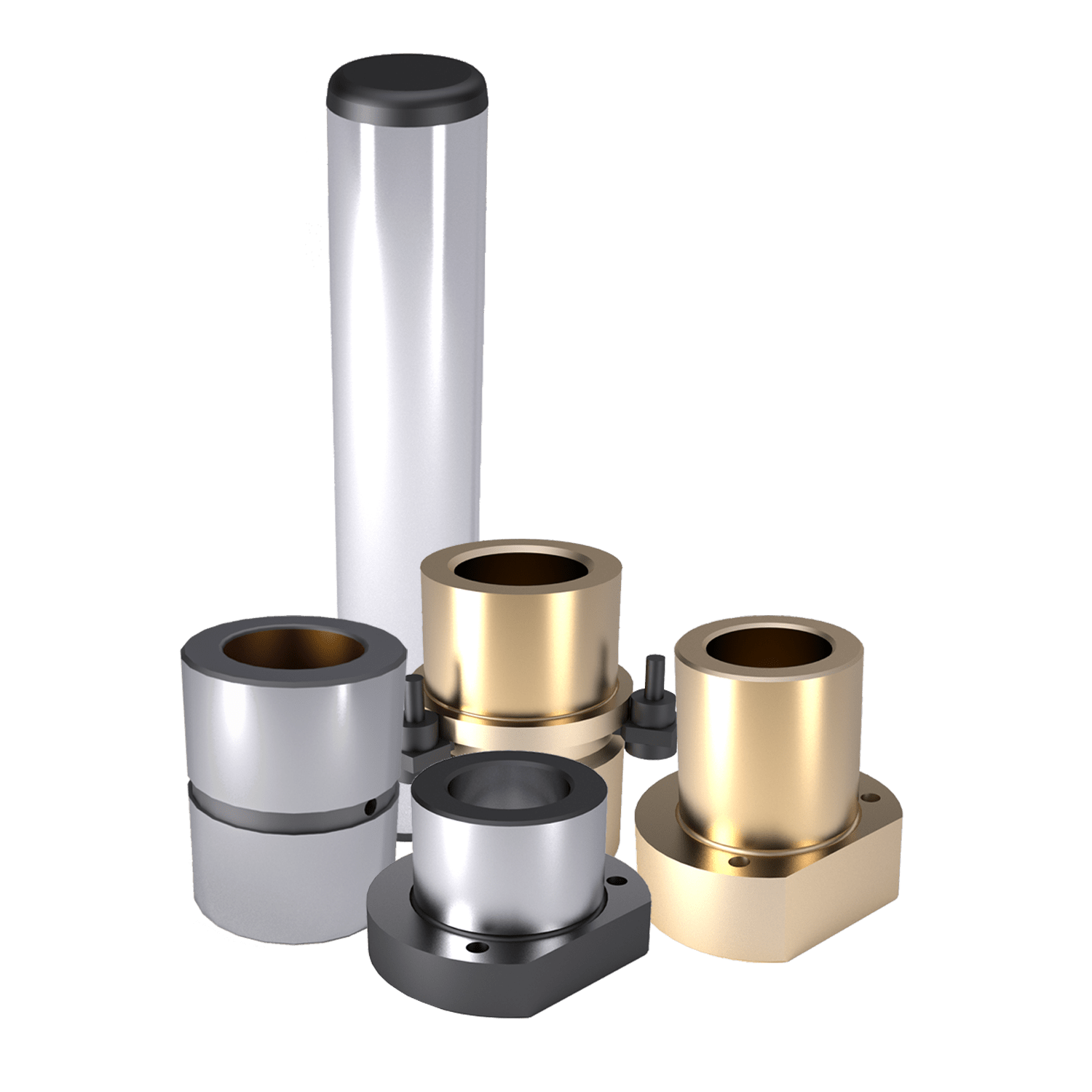

The production engineering possibilities of FIBRO allow the manufacture of three even finer tolerance classes for the already exact guide pillars and bushes. This makes it possible to achieve exactly defined guide clearances for sliding guides or initial loads of ball guides.

Depending on the application, we offer guide elements for selfassembly of custom-made die sets or devices in various designs. These include sinter sliding, ball or roller guides as well as lowmaintenance sliding elements for round or flat guides.

Especially our ball guides are not only Intended for mould making and tool manufacture. It does not matter whether in measuring or dental technologies, mechanical engineering or in the optical industry. If precise movements are to be carried out, our ball guides prove themselves time and again.

Our team will gladly lend you its support, should you have any questions regarding the correct pairing of guide bushes and pillars.

The construction and layout of components for production require a lot of time and expertise. Both are limited and costly resources.

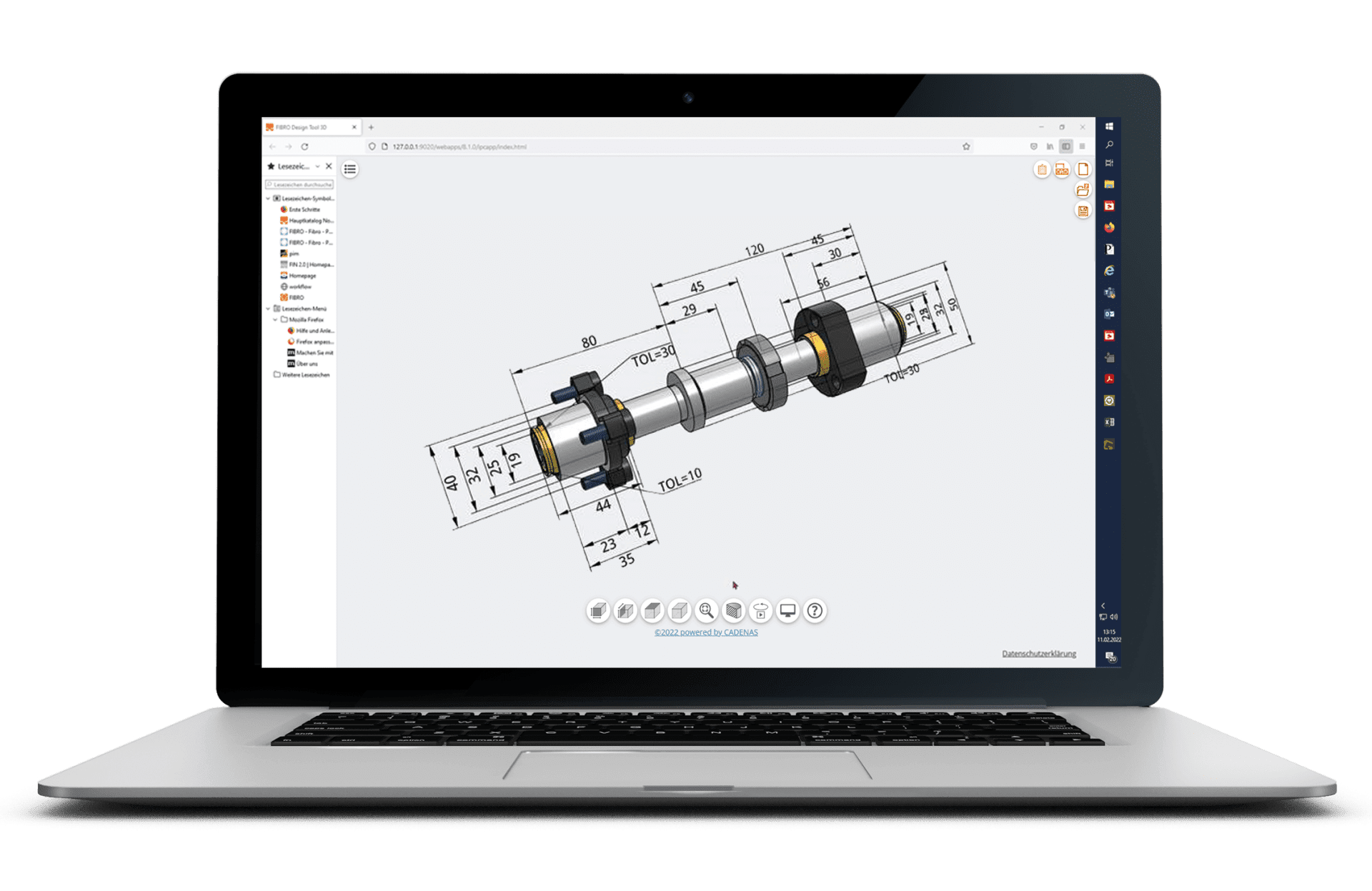

To support you the best way possible with our expert knowledge in the user-specific selection of the suitable products, we have developed the FIBRO 3D Interactive Product Configurator.

The configurator includes our entire portfolio of guide elements and allows an individual selection of guide pillars and bushes.

Whether bronze coated or bronze plated guide elements, sinter sliding, ball or roller guides as well as low maintenance sliding elements – configure the guiding unit that optimally suits your specific application and tolerance requirement.

You receive your ready-to-order product directly as a CAD download.

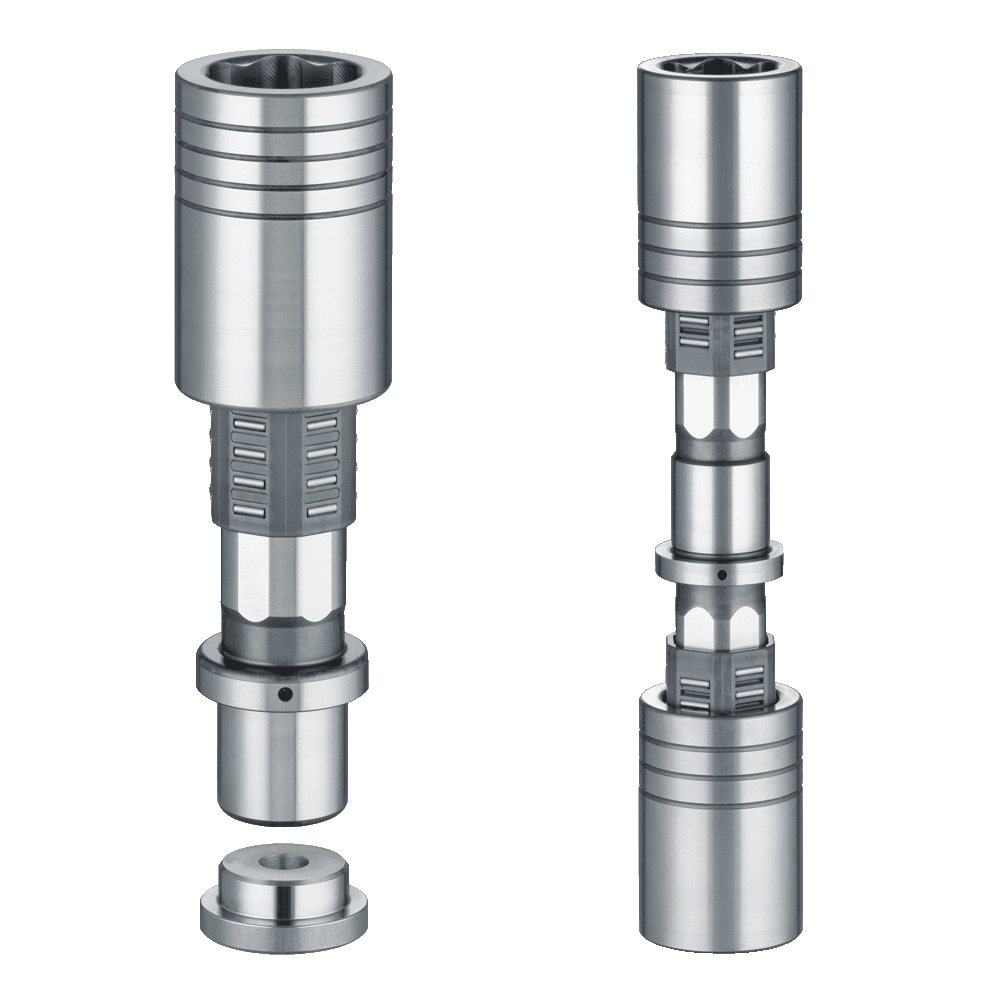

Printed circuit boards, chip cards, LED‘s, semiconductors or lids for the food industry, all of which are manufactured with foil stamping technology, require a die set with high precision guides in order to achieve an extremely narrow cutting gap.

With a high contact surface for needle rollers, our guide unit MILLION GUIDE is best suited for this purpose.

This way, the guide unit MILLION GUIDE achieves a high level of rigidity, stablility and a very high guidance accuracy.

For long travel distances with moderate loads, recirculating ball bushes are an excellent alternative to ball guides.

The ECO-LINE guide elements provide a low cost, but not inferior alternative to the other guide bushes with collar or flange. They are interchangeable with them easily and useful if you do not have high precision requirements.

THE ECO-LINE PRODUCT RANGE INCLUDES SO FAR:

The ECO-LINE guide bushes with solid lubricant rings are the link between the guide bronze guide bushes with solid lubricant nests and the guide bushes to DIN-ISO. They meet the requirement for a stable guiding with low maintenance.

Our maintenance-free sliding elements found in tool and machine for linear and rotary movements for years use. The base material is supplemented by solid lubricant depots, which provide lubrication. After this one-time initial lubrication sliding elements over a long period maintenance free. The fullness of this product range is vast range of applications. In addition, of course, also special designs according to your wishes at any time.